Build

Clean installation boosts offshore wind credentials

Petrofac is helping the Dutch Government to meet its total target capacity of 3.5 Gigawatts of wind energy production offshore by 2023, through the installation of five 700-megawatt High Voltage Alternating Current (HVAC) platforms (substations) as part of its North Sea offshore grid connection.

On this page

Select anchor link

Scope

Engineering, Procurement, Construction & Installation (EPCI)

Client

TenneT

Key facts

Building our reputation in the European offshore wind market

In 2019, TenneT, the Dutch-German transmission grid operator, awarded Petrofac a contract for the Engineering, Procurement, Construction and Installation (EPCI) of the Hollandse Kust Zuid (HKZ) Alpha and Beta High Voltage Alternating Current (HVAC) platforms. The first two of the five HKZ standardised concept transformer substations planned, the Alpha and Beta platforms are scheduled to become operational in 2021 and 2022.

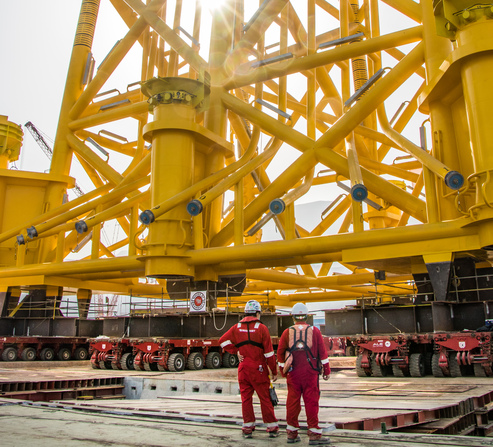

Jackets built in the UAE and transported to the North Sea

Both jackets for the project were fabricated in the United Arab Emirates (UAE). Our detailed engineering calculations, thorough project planning and comprehensive risk assessments of the loadout operations ensured the safe handling of both jackets and their associated foundation piles prior to sail away.

Following a safe one-month voyage from Eversendai Offshore’s Ras Al Khaimah facility in the UAE, the Alpha jacket arrived onsite in the North Sea in September 2020, where it was lifted into position in a water depth of 21 metres.

The Beta jacket, the second of the two transformer substations for the HKZ offshore wind farm was subsequently installed in June 2021. The installation of the Beta jacket foundation involved several complex lifts using four cranes, and our client, TenneT, applauded our work in executing these lifts safely and effectively.

Working with our partners to reduce project emissions

Both jackets were installed by Heerema Marine Contractors using the heavy lifting vessel, Sleipnir. This mammoth ship is the largest in the Heerama fleet and is recognised as the world’s most sustainable semi-submersible crane vessel.

This was the first job undertaken by Sleipnir in the offshore wind sector and the complete installation was performed while running on emission-reducing LNG fuel. This helped to reduce carbon dioxide (CO2) emissions by 25%, nitrogen oxides (NOx) by 92% and sulphur oxides (SOx) by 99%. In addition, particulate matters were reduced by around 99% compared to the use of a traditional marine gas oil crane vessel.

The past year has been characterised by uncertainty due to the COVID pandemic, not only for TenneT, but for our contractors and suppliers too. Nevertheless, together we succeeded in achieving this performance and we can be proud of that.