-

Home

- Services

-

Our work

- When innovation hits the road

- Large-scale integrated, multi-asset decommissioning

- The dawning of Australia’s decommissioning sector

- Transforming Duqm – an engineering marvel

- Ultra-efficient elixir of life for NEO’s GPIII

- Extending asset life in the Gulf of Thailand

- Concept Select - Greater Buchan Area Development

- Arrowsmith - one of world's first green hydrogen projects

- Assuring competency in a distributed workforce

- Life-of-field development planning

- First-of-a-kind waste-to-fuel plant

- Wheatstone liquefied natural gas project, Australia

- Large-scale EPC on a remote island

- Maintenance and integrity management system support

- Petrolytics: saving asset owners time and money, United Kingdom

- Value adding engineering

- Nimble engineering reduces total installed costs

- Alternative approach to late life asset management and decommissioning

- Construction skills training centre supports Algerian nationalisation

- Pioneering Well Operator delivery model

- Contract extension reflects excellent record in Iraq

- State of the art facilities introduce trainees to onsite working

- Developing the workforce of the future in Oman

- Building the Middle East’s first heavy oil development

- Stellar safety performance and a focus on in-country value for Malaysia’s RAPID project

- Technological innovation driving safe, smart and on-time project delivery

- Flexibility critical to complete final link in vital TurkStream project

- Expertise in logistics supports unique modular project delivery

- Emergency response – anywhere, anytime

- Connected workers deliver ultra-efficient maintenance

- Award winning delivery of Oman’s largest upstream project

- A truly local approach drives incredible value for Oman refinery

- Caspian technical training centre provides enhanced programme to Azeri recruits

- Maintaining uptime on the BP Rumaila field

- Our delivery know-how transcends oil and gas in the UAE

- Supporting Germany’s Energy Transition: the complex Borwin wind project

- Mega downstream project to create world-class facility

- Gas field mega project delivered in record time in a challenging environment

- Oil and gas mega project delivered in a challenging environment

- A mega project in Oman completed on time and below budget

- Petrofac’s renewable energy record enhanced by Scotland’s Seagreen project

- Digital innovations further enhance brownfield delivery model

- Well decommissioning: shared risk, well rewarded

- Outsourced support in UK North Sea

- Looking to the future of floating offshore wind

- Delivering the Hollandse Kust Zuid offshore wind platforms

- Achieving milestones: A glimpse into the Erawin project

-

Value adding engineering

DESIGN

Value adding engineering

Optimising design to support brownfield modification project

On this page

Select anchor link

Engineering services

Brownfield modifications

Region

Delaware Basin, USA

Highlights

Reduction in pipework

9%

Pipework removed

221ft

Reduction in valves

20%

Savings delivered in phase I

25%

Optimising design to minimise cost

Our client came to us to test our engineering capability on a small number of commissioning-based changes required to its existing Saltwater Disposal (SWD) unit design.

During these modifications we identified inconsistencies in the base design package and opportunities to optimise the design to reduce materials and construction costs.

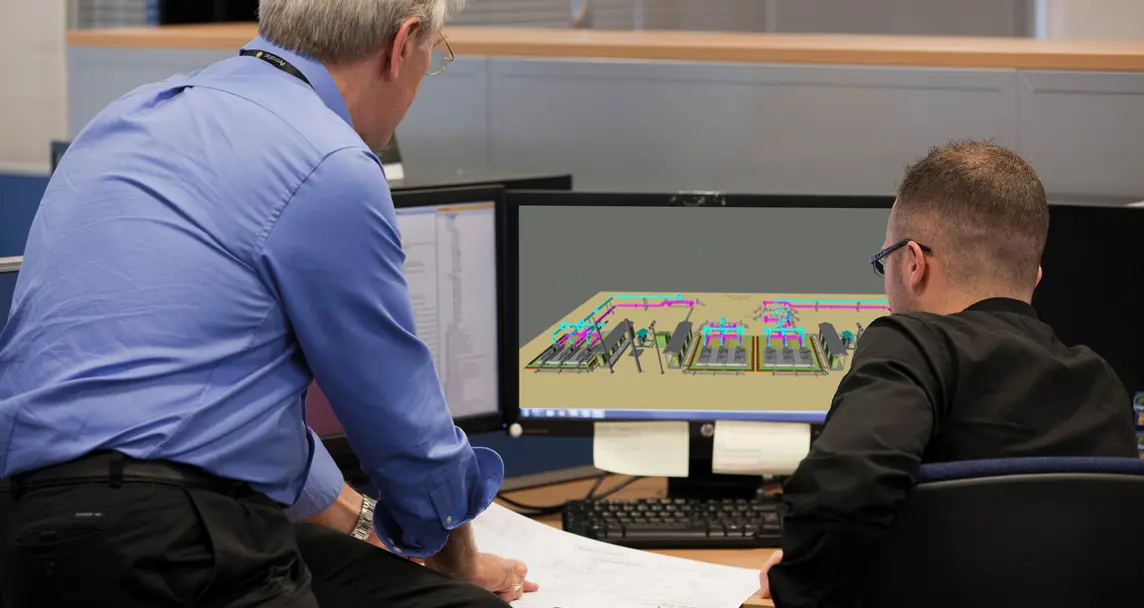

We kicked off the project in June 2019, focusing on optimising the design, working extensively with a 3D model initially, to obtain stakeholder input and buy-in to the changes we were proposing.

Value engineering delivers results

We embedded best practice from previous sites and incorporated any changes suggested by our client’s construction and technical teams. We then fully re-worked the mechanical and electrical & instrumentation engineering packages. Through this activity we:

- Significantly improved the quality and accuracy of the 3D design model

- Simplified the layout and applied standard, fit-for-purpose isolation philosophies

- Ensured consistency across the deliverables from P&IDs and 3D design model through to construction drawings (isometrics, foundation drawings, plot plans, termination drawings, etc) and bill of materials / material take-offs

- Provided 35 additional deliverables to support procurement, efficient construction, and maintenance on site

- Solution developed with ‘standardised design’ in mind

Building for the future

We consolidated this engineering scope, delivering a comprehensive scope of work document, with associated reference package, enabling the client to undertake a meaningful competitive tender process for a future program of standardised SWD builds.

Key results of this engineering work were a 9% reduction in pipework and a 20% reduction in valves, along with the removal of several other high-cost items.

By using repeatable materials, pre-fab enabled solutions and reducing the engineering and ‘as-builts’ for future sites, this one-off engineering cost will be covered by savings on the total installed cost from the first site alone.