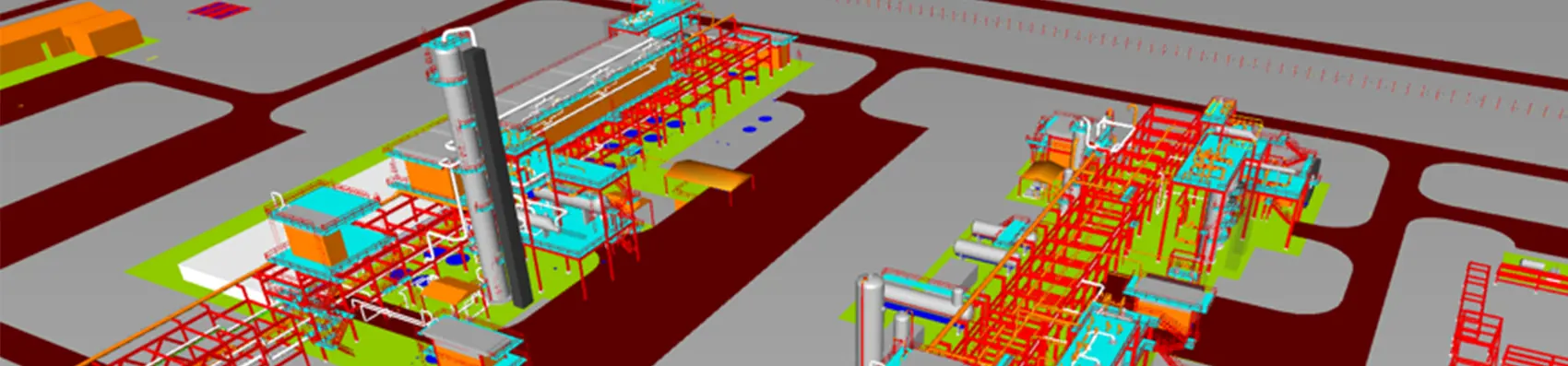

Front-end engineering design (FEED)

Our experienced engineers guide projects from concept through FEED and into execution, providing continuous advice and solutions throughout. This wraparound support provides opportunities to mitigate against regulatory, technical and execution risk in later project stages, while applying our EPC experience to optimise designs.

Support across sectors

Whether onshore, offshore or subsea, we have the knowledge and experience to manage all project scopes – for new build and brownfield modification projects. We deploy our skills to support hydrocarbon and energy transition infrastructure developments, including offshore wind, carbon capture, utilisation and storage (CCUS), green hydrogen and waste-to-value (waste-to-x and e-fuels) sectors.

Energy transition |

Offshore and subsea |

Onshore |

| Wind farms - jackets and topsides | Fixed structures | Well sites and flow lines |

| Electrical systems and distribution | Floating facilities | Export pipelines |

| Pipelines - onshore, offshore and subsea | Reception facilities | Central processing facilities |

| Waste to energy/fuels | Metering | Gas processing |

| Infrastructure and utility support systems | Risers and flowlines | Oil processing |

| Decarbonisation and emissions reduction | Umbilical and controls | Refineries |

| Hydrogen plant (blue, green and grey) |

Subsea production systems

|

Degassing stations |

|

Manifolds and structures |

Offsite facilities |

Technology neutral

We take a practical and pragmatic approach to every FEED project. And, as a technology-neutral provider, we are free to select the best solutions for your project.

Related services

Constructability at the core

When we execute a FEED, we commit to providing reliable costs and schedules alongside safe, constructible, and operationally efficient designs. We draw on the expertise of our construction and commissioning teams during FEED to enhance our solutions.

Security of cost and schedule

We also leverage data from our EPC and operations delivery teams to ensure certainty and predictability. By using real-time supply and demand data, we drive cost surety and can expedite the procurement of long-lead items, reducing project schedules.

PROJECTS

200

Our front-end solutions are enhanced by our delivery of over 200 EPC projects

SCHEDULE

12

By integrating our services, we can improve schedules by up to 12 months

EXPERIENCE

25

We bring more than 20 years' project development experience

Improving performance

Our operations analysis is based on live data and our knowledge of real operational challenges. This helps us define best-fit designs that assure ultra-efficient future operations and deliver modifications with minimal impact to asset operations.

Integrated services unlock value

We integrate our services where we see opportunities to improve schedules or create cost-saving strategies. This may involve fast-tracking projects by integrating concept, pre-FEED and FEED phases, procuring long-lead items early or adopting a modular fabrication approach to streamline construction and reduce total installed costs.

Watch our video:

Talk to us: