THE HUMBLE VALVE IS THE UNSUNG HERO OF OUR INDUSTRY. MILLIONS OF VALVES ARE WORKING DAY AND NIGHT RIGHT NOW ACROSS OUR PROJECTS. MINIMISING DOWNTIME, OPTIMISING ENERGY CONSUMPTION, MAXIMISING OPERATING EFFICIENCY, AND ESSENTIAL FOR SAFE OPERATIONS, NO OIL AND GAS INSTALLATION COULD FUNCTION WITHOUT THEM. HERE’S WHAT MAKES THEM SO SPECIAL

THE WONDERFUL WORLD OF VALVES

HOW WE WORK

PUBLISHED JUNE 2022

The global oil and gas valves market is expected to surpass US$12.5 Bn by the end of 2022.

Valves come in all shapes and sizes but have a lot in common: starting and stopping flow, regulating it, relieving pressure build-ups.

The global outlook

All shapes and sizes

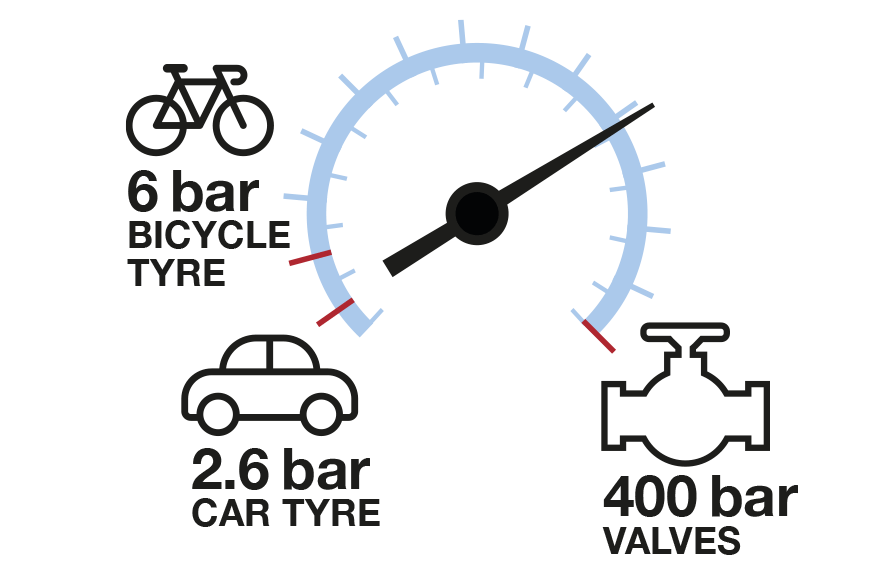

Valves can experience pressures of more than 400 bar so they have to be much tougher than the valves in the tyres of your car. There are even API 20,000 (1380 bar) rated high pressure valves, normally associated with well heads.

Valves can be tiny or gargantuan, ranging in size from needle valves at ½ inch to gate valves with a height of more than 10 metres.

What makes them so special

Valves can face temperatures of more than 700°C (which is at or approaching the melting point of many everyday metals such as zinc, aluminium and magnesium). Many are also designed for extreme low temperatures down to -196˚C for services like liquid nitrogen.

Valves at Petrofac

Depending on the project size, big refinery projects can have as many as 120,000 valves.

,000

The heaviest valve we’ve used on a project was a 56” ball valve weighing 30 tonnes for a gas export pipeline at the Galkynysh Gas Field in Turkmenistan – the world’s second largest gas field. That’s the same weight as five elephants.

0

"

0

tonnes

0

It’s important to optimise the design and type of valves being used on projects. On the Galkynysh Gas Field project we replaced many ball valves with high performance triple offset butterfly valves. These give tight shut off, are lighter in weight, occupy less space and maintenance costs are low compared to ball valves.

Gathering Centre oil and gas project

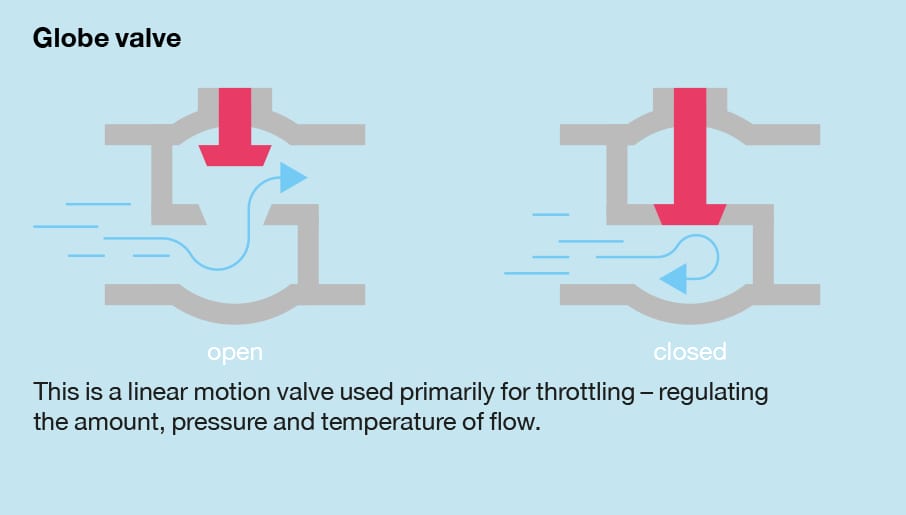

Globe valves 3%

Check valves 5%

DBB 9%

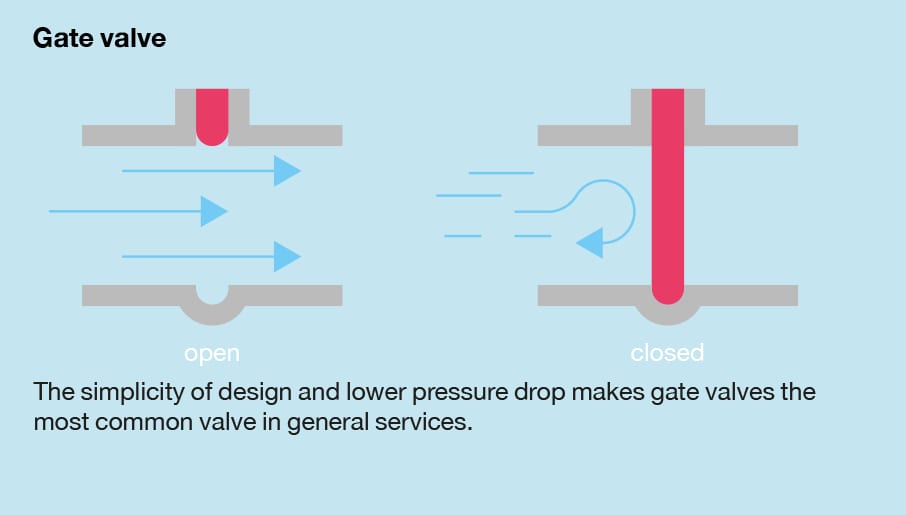

Gate valves 15%

Ball valves 68%

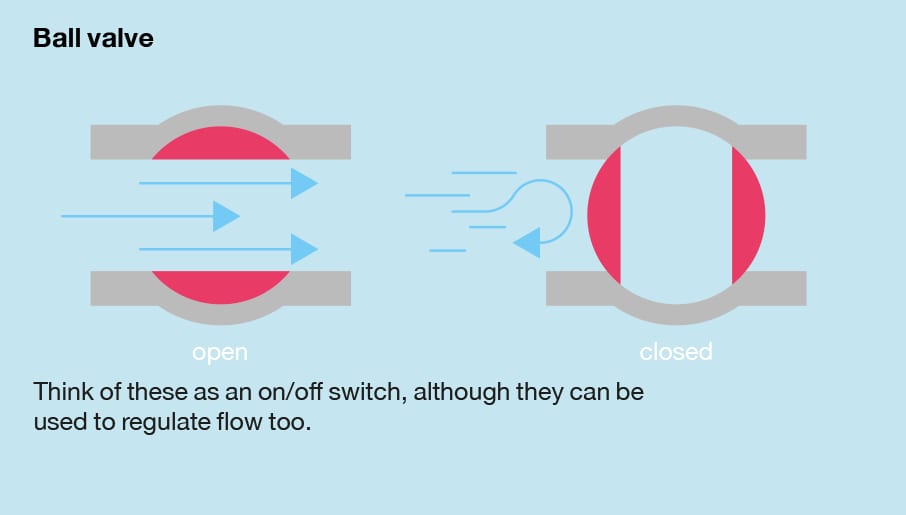

Here’s the breakdown for a gathering centre in Kuwait, which processes crude oil and associated gas. In any plant, starting and stopping flow (which requires isolation valves) is the most common function. So, you’re likely to find lots of ball valves in the upstream segment.

Clean fuel refinery project

Other valves 1%

Ball valves 5%

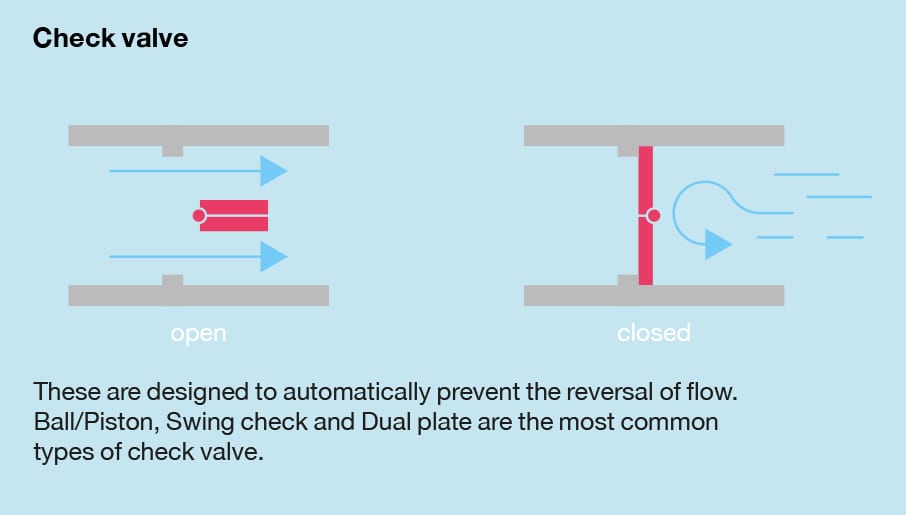

Check valves 7%

Globe valves 28%

Gate valves 59%

In refineries, gate valves are the most common isolation valves; these cope well with higher-temperature applications. This mega downstream project in Kuwait illustrates the typical breakdown on a refinery.

In the North Sea the most prominent valves are ball valves, used across instrumentation systems, small bore applications, and large high-pressure applications. They are typically quarter turn so easy to operate.

A Christmas tree valve is a ‘manifold’ or system of valves that act as a control point for production between the subsea and topside operations. They manage chemical injection and treatment, pressure relief, and are crucial for safety with gauges showing pressure below the well.

One of the biggest valves our offshore valve specialists have come across was a 36-inch riser actuated ball valve that weighed 22 tonnes.

Another unusual valve used offshore is a TigerTooth trimmed control valve – which is a severe service control valve. It’s designed for high pressure drop applications and reduces noise, with the flow coming through the centre of the board and cascading through the ‘cage’.

What about valves offshore?

tonnes

0

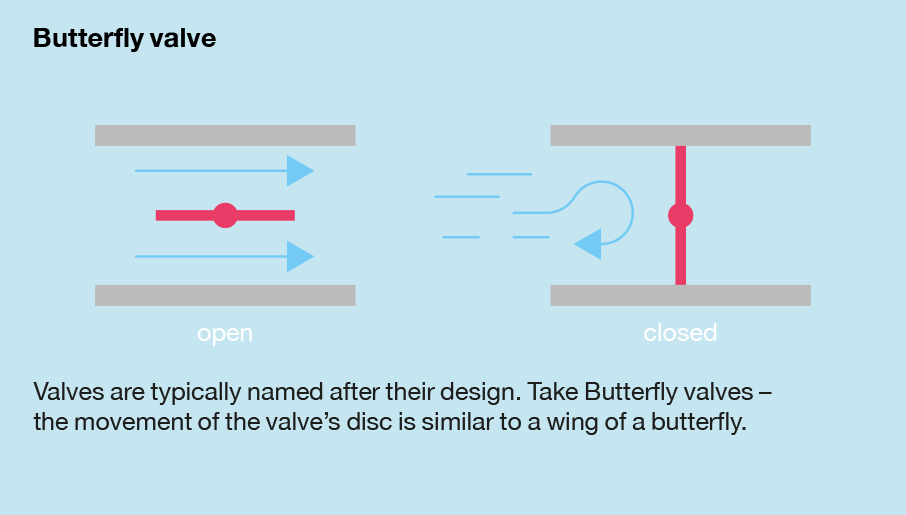

It’s all in a name… Valves are typically named after their design. Take Butterfly valves – the movement of the valve’s disc is similar to a wing of a butterfly.

What they’re made from depends a lot on factors like service fluid and its composition, pressure, and environmental conditions. For instance, concentric butterfly valves have a rubber lining able to withstand corrosion, making them ideal for use in sea water.

We can work with anywhere between

2,000 and 3,000 different suppliers every year