MAKING MIRACLES IN OMAN

WORDS CHRISTINA McPHERSON

PUBLISHED MAY 2021

WHere we work

THE PETROFAC RESEARCH CHAIR IN RENEWABLE ENERGY AT THE AMERICAN UNIVERSITY OF SHARJAH IS AIMING TO MAXIMISE THE PERFORMANCE OF SOLAR PANELS – AND THE RESEARCH COULD HELP OUR CLIENTS IN THE REGION MINIMISE THE ENVIRONMENTAL IMPACT ON THEIR PLANTS. HERE’S HOW

CATCHING THE SUN

HOW WE WORK

There is a scene in the 1999 sci-fi film The Matrix where the lead character, Neo (played by Keanu Reeves) is fighting one of the baddies on the tracks of a subway. Apart from the actors, nothing is real. A full-size subway set was built and photographed from different angles – and then reconstructed using photogrammetry. Slow motion action in ‘bullet time’ is captured on 120 still cameras and pieced together using the technique, which analyses photographs to create extraordinarily accurate 3D models, replicating how they would move in time and space. The same process is used in the film industry to create crowd scenes and digital stunt doubles.

Sadly Petrofac has not yet created a digital double for Kevin Vardy, manager of Digitalisation Services for Engineering and Consultancy Services (ECS), but he is championing the technique as a way to save time and money in the maintenance of offshore assets.

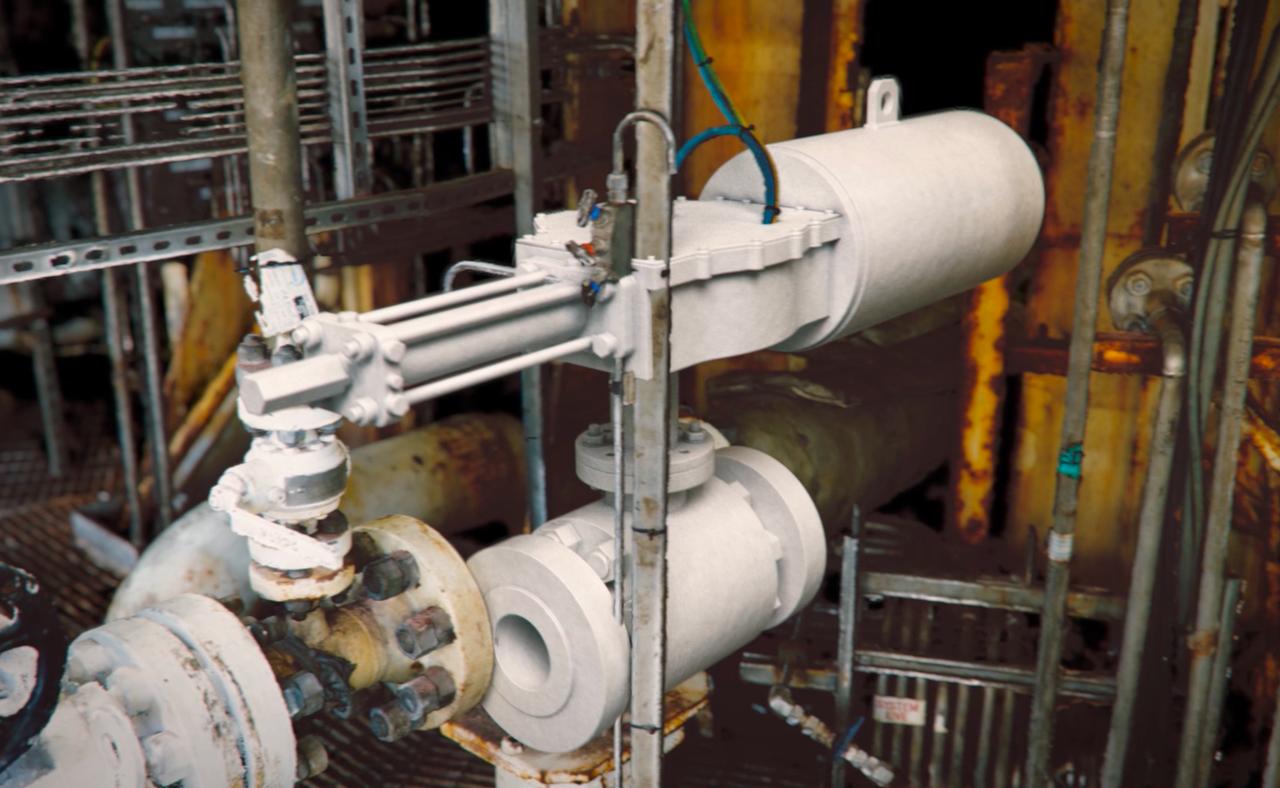

Take an issue like a pin-hole leak appearing in ageing pipework on an offshore oil and gas facility. The remedial process at the moment is time-consuming, involving risk assessments, scoping, commissioning and often requires sending a team out to the asset to conduct a survey which reports back to the design team, before manufacturing and replacing the part.

“It can be hard to visualise the technical work required,” explains Kevin, “and there is potential for inaccuracies in some cases where the measurements have to be done manually in the field.

“Sometimes there are small teams permanently resident on the asset who can take the measurements, but you usually have to send out a team with all the costs that involves – their time, transfer and helicopter costs, accommodation. Then there’s all the to-ing and fro-ing, the iterative clarification process between Onshore Engineering and Offshore teams.”

THE PHOTOGRAMMETRIC FUTURE OF OFFSHORE MAINTENANCE

HOW WE WORK

WORDS RICHARD LOMAX

PUBLISHED AUGUST 2021

IN WHAT SOUNDS LIKE A PLOTLINE FROM THE MATRIX, PETROFAC IS USING THE RS2 MOSAIC DIGITAL TWIN PLATFORM TO DEMO AN INNOVATIVE APPROACH TO MAINTAINING OFFSHORE ASSETS

One of Petrofac’s projects in New Zealand

Leading the way: American University of Sharjah working with Petrofac to optimise solar farm efficiency

CLOSE RANGE PHOTOGRAMMETRY

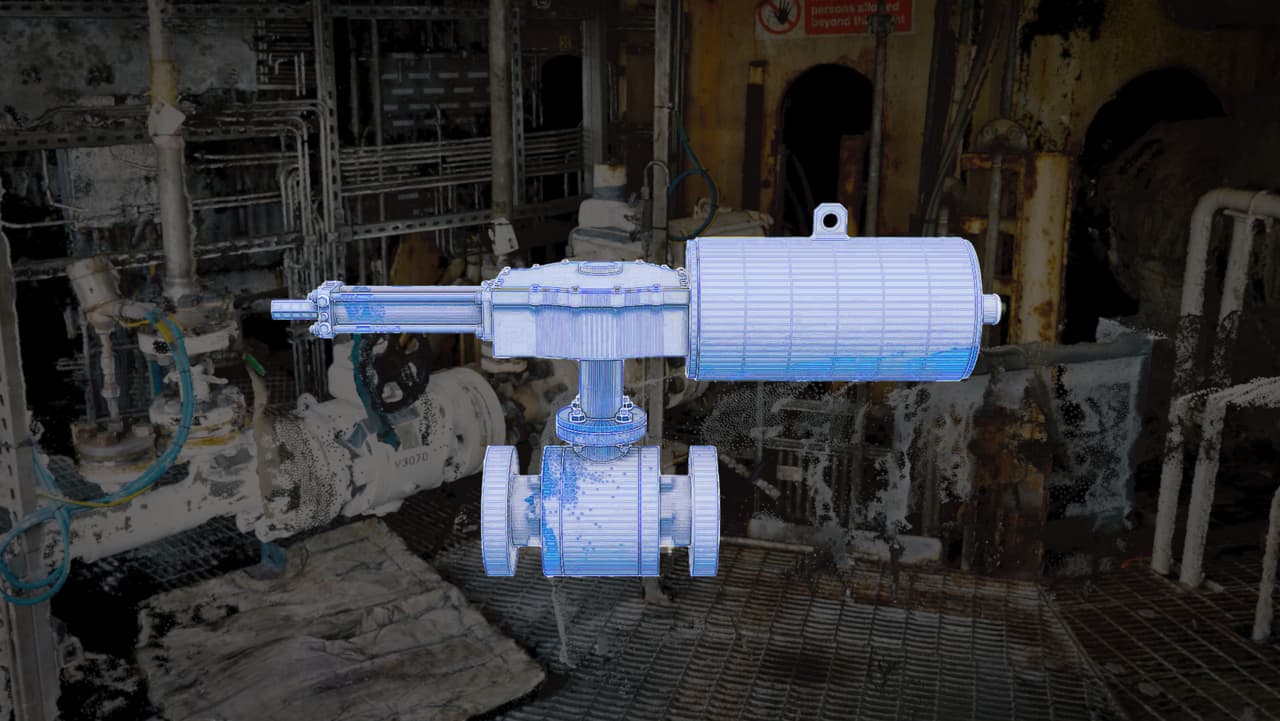

But what if the core site team could gather the data themselves using Self Capture Point Cloud Photogrammetry, and make that available to the design team through a digital twin of the asset? A lot of the time and cost is stripped out. You can react faster to priority repairs, and everyone has a better understanding of the technical work required.

This is not the stuff of science fiction. In what is believed to be a first for the UK offshore energy industry, Petrofac has teamed up with the Asset Information Services division of James Fisher, a long-established British marine services specialist, to prove the concept.

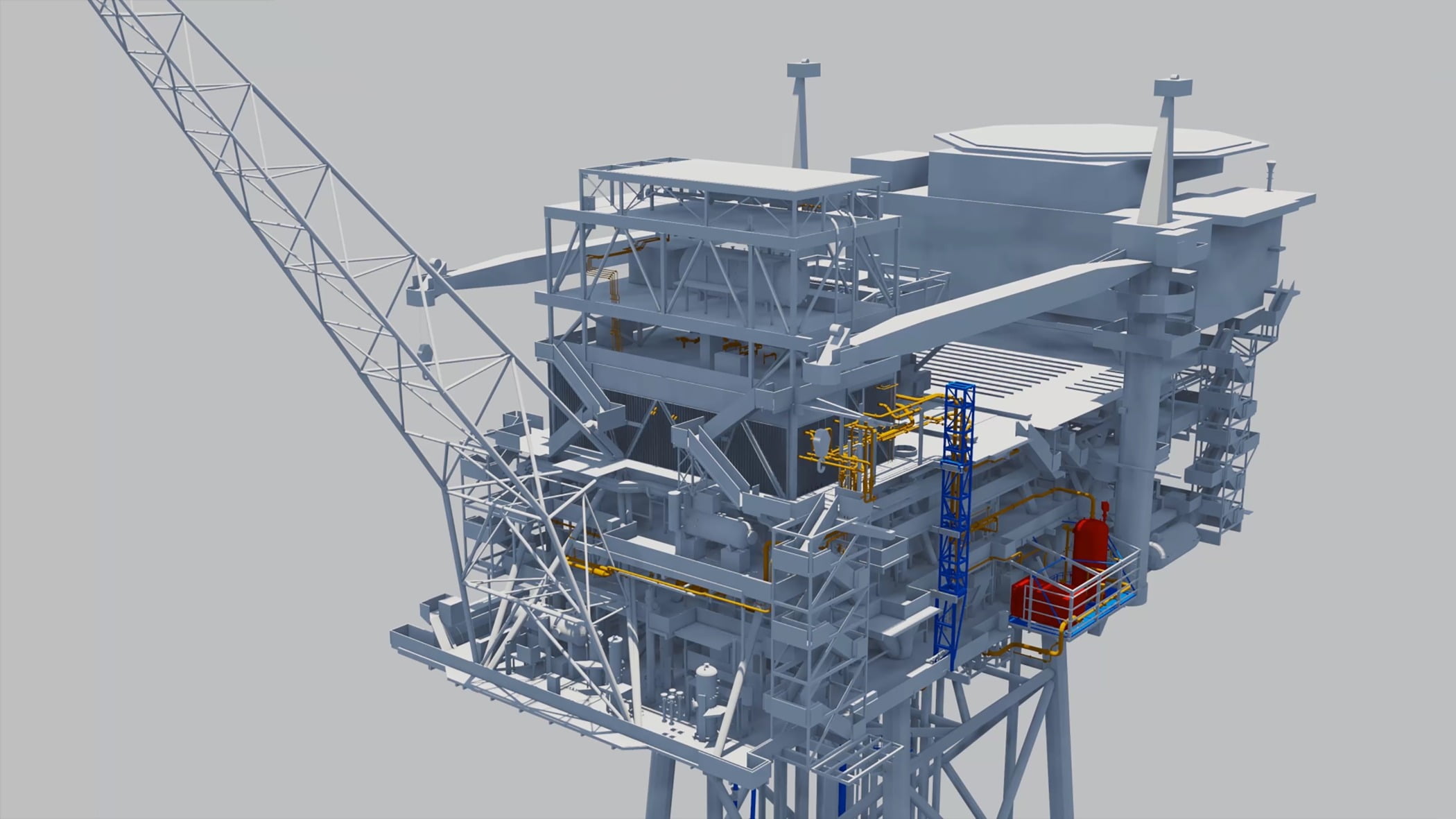

Using the company’s RS2 Mosaic Digital Twin platform (a name that could have come straight out of The Matrix), Kevin and his team have demonstrated impressive results on a real-life problem with seawater supply pipework, or ‘spool’, on a Floating Production Storage and Offloading (FPSO) vessel in the North Sea.

POINT CLOUD MODELLING

“We bought a camera kit from James Fisher, gave it to the asset team to take the pictures which were then used to create a Point Cloud Model and uploaded into a digital twin,” says Kevin. “The brownfield engineering team were then able to use the digital twin to understand exactly what was required, and for the design engineers to generate the isometric drawings for the replacement spool manufacturers. Our biggest concern was would the images be accurate enough to manufacture? They were, within a 2-3mm tolerance, and we were able to do it without sending anyone offshore.”

In an environment with a constant focus on health and safety, cost and the drive to net zero carbon, and where facility operators are keen to reduce the number of non-core crew personnel they deploy to an asset, this could be a significant development. The benefits include better planning and estimating; lower costs because there’s no need for offshore surveys – virtual surveys can be carried out from the safety and convenience of an onshore office; better transfer of survey data with the productivity gains that that brings. And faster response times.

“We’re using technology to accelerate what are often critical path activities, for example in new subsea tiebacks that need piping tie-ins during planned production shutdowns. It’s a test case that could easily read across to other assets where design and remanufacturing challenges could benefit from having highly accurate, readily available digital replicas, like wind turbines. The potential is very exciting,” says Kevin.

As the oil and gas industry focuses on maximising returns from existing assets while it transitions to a lower-carbon future, Petrofac’s digital innovation and collaboration with technology leaders like James Fisher can help its clients extend the life of their fields, reduce offshore travel and unlock significant value through increased uptime and cost efficiencies. Offshore wind operators will be following developments with keen interest too.

‘Benefits include better planning and estimating; lower costs because there’s no need for offshore surveys; better transfer of survey data. And faster response times.’

One of Petrofac’s projects in New Zealand

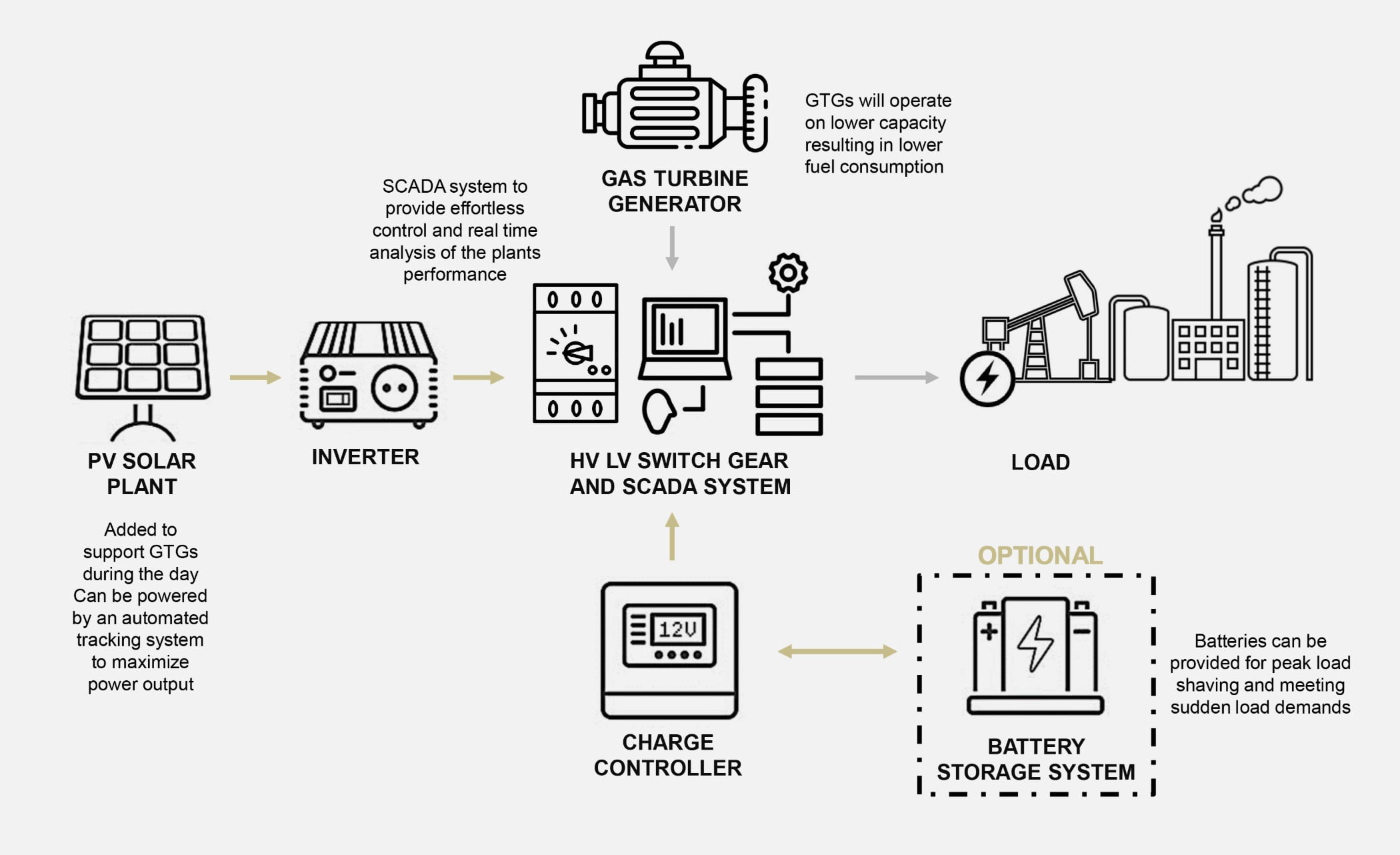

How it works: the solar/gas hybrid solution

Compared to refineries, solar photovoltaic farms are relatively simple projects, and Petrofac has the in-house capability to develop, design, construct, and procure the materials and equipment needed for solar projects.

“We are focused on promoting our solar PV capabilities to oil and gas companies and have a competitive advantage in this area compared to organisations that build solar farms for the generation of electricity for the public,” explains Mark. “We are very familiar with the construction and operational challenges of working in a major hazard industry.”

“We can offer end to end services that support the full life cycle of solar projects, from system and technology assessment and selection, to project development support through to design, construction, operation and maintenance.”

Mark believes that the research AUS is carrying out will be invaluable in maximising the life cycle of solar farms in the future. Manufacturers claim very high efficiency rates, but these are in perfect conditions, and of course perfect conditions don’t exist, he says.

“The degradation in performance can be quite dramatic, so it’s equally important to consider those aspects in your design and construction. If you can squeeze more economic value out of a solar farm in terms of performance, revenue and power output, this equates to cost behind the meter – as you’re saving gas which is itself a commodity.”

“Clean energy and renewables are a burgeoning market globally as countries strive to achieve the climate objectives agreed in the Paris Agreement.”Mark Cowley

GAMING CROSSOVER

Kevin’s work with Petrofac’s Operations and Engineering teams highlights how far and fast engineering is evolving, with exciting crossovers with other disciplines.

The team of engineers and scientists using the same photogrammetry technique to restore Notre Dame in Paris after the catastrophic fire in 2019 is led, for example, by an architect who is also a computer scientist. And while The Matrix film highlighted the glamorous potential for digital twin technology 20 years ago, young engineers entering the energy industry today may be more familiar with photogrammetry from its use in video games like Assassin’s Creed. The day after the Notre Dame fire, the game’s makers offered the detailed digital models it had previously created of the famous cathedral as a setting for its game.

Replacing pipework using a digital twin is unlikely to be a plot-line in any Matrix remake. But in our world the potential of the technology to solve real-life problems is setting engineers’ pulses racing – and starting to excite a few client-side accountants. ‘There’s no turning back’, as they say in the movie. ‘Are you going to take the blue pill or the red pill?’

A digital twin of Notre Dame in Paris helped restorers rebuild the cathedral after a devastating fire