MAKING MIRACLES IN OMAN

WORDS CHRISTINA McPHERSON

PUBLISHED JANUARY 2021

WHere we work

IT’S BEEN ONE YEAR SINCE PETROFAC AND W&W ENERGY JOINED FORCES IN THE UNITED STATES TO GROW OPERATIONS IN THE PERMIAN BASIN. W&W’S LOCAL KNOWLEDGE COMBINED WITH PETROFAC’S GLOBAL ENGINEERING EXPERTISE MAKES FOR A STRONG PARTNERSHIP FROM WHICH CLIENTS IN THE REGION CAN BENEFIT. PRESIDENT OF PETROFAC AMERICA, JOHN GLITHERO, AND PRESIDENT OF W&W ENERGY, JASON WATERS, REFLECT ON THE OPPORTUNITIES AND TELL US HOW THEY’RE PAVING THE WAY FOR FUTURE SUCCESS

MEETING

OF

MINDS

WHERE WE WORK

The size of the Permian Basin in the USA is hard to grasp: 75,000 square miles, 250 miles wide and 300 miles long, the basin spans vast swathes of west Texas and south-eastern New Mexico.

The area is noted for its rich petroleum, natural gas, and potassium deposits; ‘nodding donkeys’ as far as the eye can see dot the flat, desert-like landscape; they are now mixed with wind turbines and solar farms, due to the area’s fast growing renewables sector.

It’s a challenging environment, and you need grit and determination to work here, something that President of W&W Energy and local resident Jason Waters knows all about. He is from a small town “right in the middle of an oilfield” in the Permian Basin.

Jason took over the family business after leaving the US Army. The company, which has been operating in the Permian since 1982, offers maintenance pipeline and construction services in the basin.

“It’s a tough market – and it can change quickly. I’ve lived it, I grew up here, I’ve seen it happen,” he says, when asked about the challenges of the environment. “We’ve seen it again last year with the downturn. All you can do is adapt and roll with the punches. As the old saying goes: never waste a good crisis. We’ve used the opportunity to invest in our business so that we’re in a strong position when the market returns. And it will return.”

IT’S BEEN A SMOOTH TRANSITION

Petrofac and W&W Energy joined forces just over a year ago. The acquisition has allowed Petrofac to gain a foothold in a new onshore operations, maintenance and construction market – one that has significant potential for growth. The Permian Basin has been producing oil for a century but has vast reserves and enormous untapped potential – the United States Geological Survey, for instance, estimates that there are 46 billion barrels of recoverable oil, 280 tcf of natural gas and 20 billion barrels of NGLs.

Petrofac was looking for ways to enter the onshore market in the Permian, while W&W wanted to take their organisation to the next level and continue to grow.

“Together our focus is on onshore in the Permian,” says John Glithero, President of Petrofac America. “W&W is a great company with a good reputation; it had been very successful on its own, experiencing a very positive growth rate. It was at a point where Jason and his family were looking for a way to continue this growth.”

It could be said that Petrofac and W&W Energy are two sides of the same coin. The companies and the services they offer complement one another and allow them to bring something new to the market.

Petrofac’s engineering and project management expertise alongside its global track record, says John, will allow the companies to secure and work on larger projects in the future. W&W Energy meanwhile brings its capabilities in construction, field maintenance and production services.

By marrying Petrofac’s engineering capability, with W&W’s field maintenance experience, the team can offer a one-stop-shop to clients. As Jason continues, W&W Energy’s value is in its diversity. “We do so many different things from facility construction to tank and equipment hauling – enabling us to bring real value to our clients.

“One example is that typically contractors here will contract out the testing of pipelines to third parties, with any modifications and repairs being done separately. But we have our own team for this, allowing us to offer a seamless test and repair service. It’s just one of the things we do and it’s somewhat unique out here.”

One of Petrofac’s projects in New Zealand

LOCAL FOOTPRINT: PART OF THE COMMUNITY

Despite the vast size of the oil and gas producing basin, it’s home to many close-knit communities.

“There are oil fields right next to my house and office, which is definitely unique compared to a lot of settings Petrofac has historically been in,” says Jason. “The industry is literally happening around you.”

The fact that Jason and his family are local to the area was another reason that drew Petrofac to W&W Energy. They bring local client and supply chain relationships, fostered over many years, to the partnership.

“Another challenge is attracting good people during busy periods, such is the high demand. But the Waters family are well known to the people out there,” explains John.

The geology of the Permian Basin is unusual in comparison to other onshore fields – it contains several sub basins, each with their own characteristics. This local understanding of the geological conditions is essential. “If we are bidding on an opportunity, or working in an area with a major rock formation, Jason will know,” continues John. “We are also working in more than one state, so we need to understand how requirements change across the region.”

RESILIENT AND READY FOR WHAT COMES NEXT

The coming together of these two complementary companies has, from Jason’s perspective, been “a smooth and frictionless transition”.

John agrees. He says that Jason and his team are excellent to work with and that a culture of safety – and putting people first – was something that immediately united the two companies. “Our people are the greatest asset in Petrofac, and we wake up every day making sure we do the right thing for each other,” he adds.

And, while the Permian Basin, like the industry around the world, has seen a downturn caused by the uncertainty of the pandemic, Petrofac and W&W Energy have been able to weather the storm together.

Despite the challenges, they have also won new clients this year. “We’re in different markets now from when the acquisition happened – we’ve gone from only working with upstream clients to working with midstream and even a little bit of downstream,” says Jason.

W&W has been able to build up their brand in the field. “The way we present proposals and communicate with clients is much more sophisticated than it used to be because of Petrofac, and it’s got us some wins in the last three months,” adds Jason.

It’s apparent that both companies are resilient and seek out opportunities. Petrofac has already been able to use its engineering expertise to drive savings for clients, offering creative ways to re-purpose existing client inventory to support in-field improvements (see box out).

Since the merger, W&W Energy has focused on enhancing its fleet, adding a new large knuckle boom truck (one of only two of its type in the whole region) and investing in new hydro testing equipment to support its pipeline integrity service. They have both stayed busy during the downturn.

“The field is already picking up. As that continues we are in a good position to take on larger projects and have the financial strength to be able to assist customers in the procurement process,” says John.

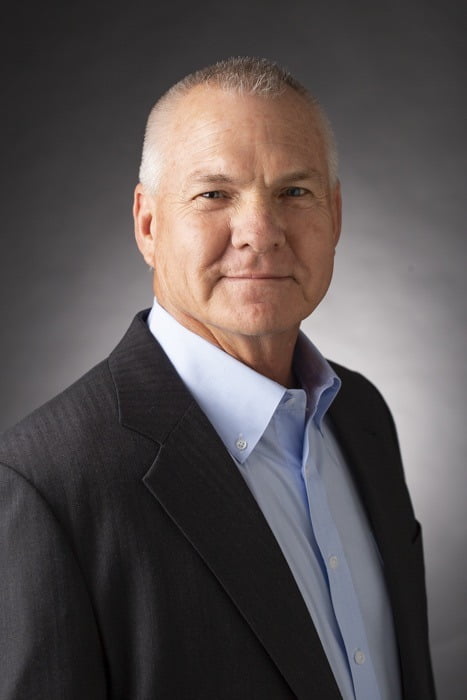

JOHN GLITHERO

President of Petrofac America

A native of Texas, John has more than 30 years’ experience in the oil and gas industry, including tenures as Senior Vice President, Business Development for Wood Group Americas, and prior to that, President of Wood Group (WGPSN). He joined us in 2017 and leads all elements of our growth and operations in the region.

JASON WATERS

W&W Energy Services President

Jason is from a small community of about 200 people in the Permian Basin. He attended the United States Military Academy and served in the US Army for five years. On leaving the army he took over the leadership of W&W Energy and over ten years grew the business into the success it is today.

ONE FOR THE HISTORY BOOKS?

The rest, as they say, is history.

“What we achieved, especially between April and July 2020, was phenomenal,” adds Construction Director Mohammed Shaheen. “As the Covid-19 pandemic intensified, we felt insulated from it, as though our site was the safest place on earth. And, as the whole world came crashing down, Ghazeer kept pushing forward.”

Ultimately, the project was delivered two months early. Some 19 million hours were safely completed, without a single lost-time incident (LTI). bp was able to put the project into production in October 2020. And this will surely go down in the annals of Petrofac history as one of the company’s most impressive performances.

Mohammed Shaheen

Learning there was unused, spare equipment within the client’s inventory, from transformers and switchboards to pumps, VFDs and control panels, they started to look at ways to release this inventory and provide immediate savings.

They surveyed every piece of existing equipment, working alongside client and vendor personnel. The electrical engineering team validated the existing power distribution equipment. And, they wrote scopes of work and requests for quotations (RFQs) for vendors to carry out the minimum modifications, refurbishment and testing required to enable the use of more than 50 electrical and mechanical equipment items that were already in the client’s inventory.

This creative, collaborative way of working has helped the client deliver vital infrastructure improvements even when budgets were constrained. New CAPEX for this first campaign will be reduced by over $1.5 million, a saving of more than 10% of the total installed cost (TIC).

NIMBLE ENGINEERING

What started out as a small scope to provide the detailed design package for the installation of water booster pump stations, evolved into a comprehensive programme to deliver a standard optimised design that would deliver year-on-year savings for a client in the Permian Basin.

During initial planning Petrofac and W&W Energy established that the client’s plan was to install between 40 and 50 of these booster pump stations over the next few years to meet its increasing production targets. With support from them, Petrofac and W&W Energy began developing a ‘design one, build many’ standardised design that would drive costs down by optimising the mechanical and electrical and instrument designs.

However, before the standardised builds could begin, the downturn saw CAPEX cut across the region. With a number of pump stations still needed to support the infrastructure, the Petrofac and W&W teams worked with the client to develop an alternative solution that would support them during this time.