PROJECTS

IN PICTURES: EXTRACTING HEAVY OIL

THE LOWER FARS HEAVY OIL DEVELOPMENT IS ONE OF THE BIGGEST UPSTREAM PROJECTS IN THE MIDDLE EAST. PETROFACTS EXPLORES WHAT’S INVOLVED IN THE COMPLEX PROCESS OF EXTRACTING HEAVY OIL

WORDS CHRISTINA McPHERSON

IMAGES CHRISTOPHE VISEUX

PUBLISHED OCTOBER 2020

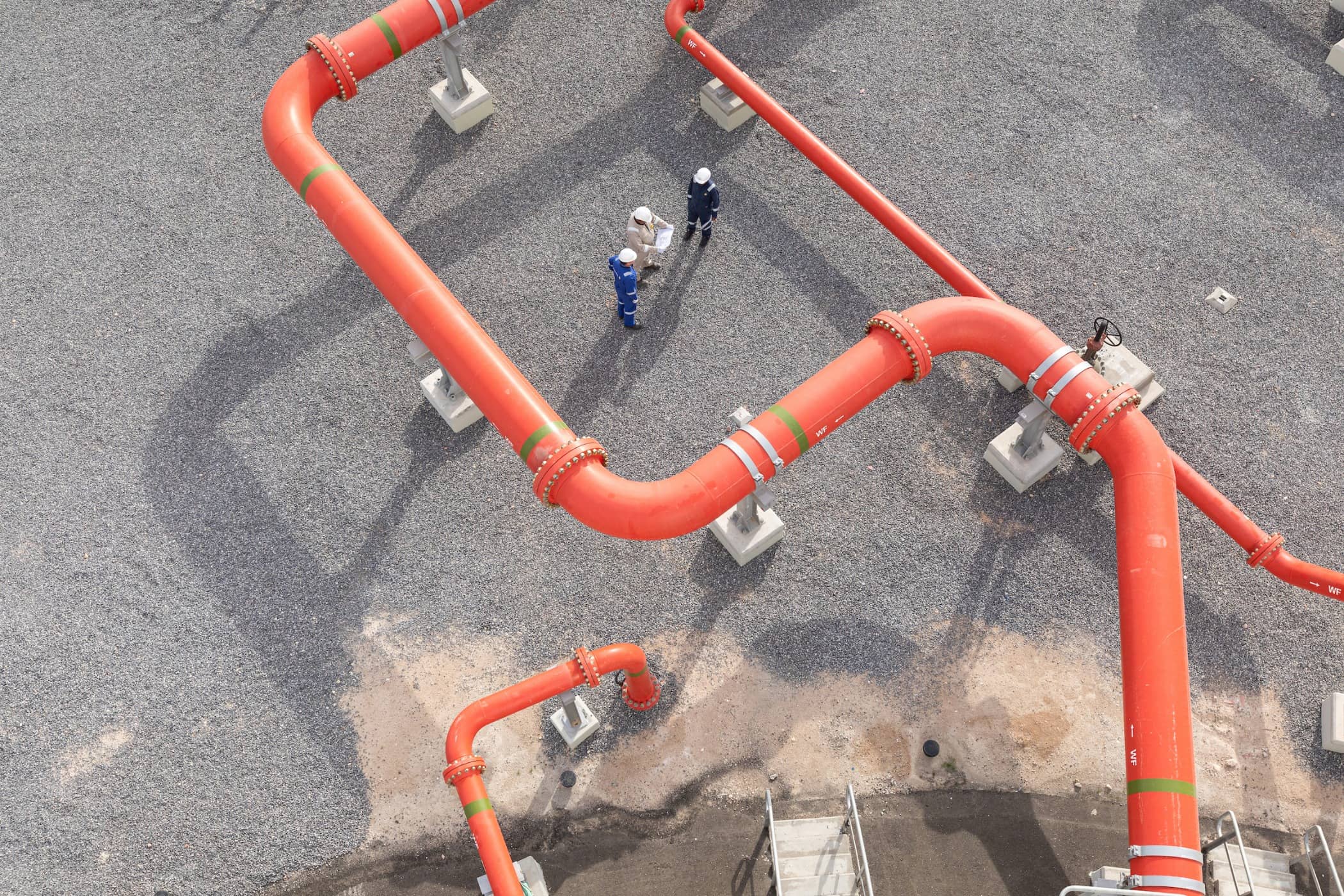

A bird’s eye view of the Central Processing Facility (CPF), constructed by Petrofac. Five years ago, desert stretched as far as the eye could see in this area of northern Kuwait near the Iraqi border. Now, the facility takes up around 7 sq km – nearly the size of Gibraltar.

Lower Fars is the first project of its kind in Kuwait. The onshore oil field known as Ratqa is estimated to contain huge volumes of heavy oil. Extracting heavy oil can be more time consuming and expensive than lighter crude because of its viscosity; however, the potential is huge.

A maze of several trunklines. The CPF connects to the field’s well blocks around 7 km away via these trunklines. A two-way system, some lines carry steam that has been generated in the CPF to the wells, while others carry the crude oil back from the wells to be cleaned and treated in the CPF. Heavy oil is exceptionally dense, meaning that it won’t flow on its own and needs to be injected with steam to be pumped out of the wells.

With the horizon in the distance, the pipelines from the Black Sea are visible in the cleared area of land; post-construction much of the area will be returned to its previous condition. (Read more about the reinstatement work here). To the bottom of the main site is the camp for workers, comprising two canteens, a gym, recreational areas, accommodation and offices. The camp was as big as the facility and home to 2,500 workers at peak.

Well drills look like blue specks across the vast desert. There are 930 wells in the 45 sq km field, split into two well blocks. These two well blocks essentially function as the nodal point for distribution of incoming steam and the initial collection of the oil.

WHAT IS THE LOWER FARS PROJECT?

In 2015, Petrofac was awarded a contract by Kuwait Oil Company (KOC) for the first phase of the Lower Fars heavy oil development programme, located in Northern Kuwait.

Petrofac is leading a consortium with the Consolidated Contractors Company (CCC).

The project is worth in excess of US$4 billion, with Petrofac’s share more than US$3 billion.

The scope of work covers greenfield and brownfield facilities and includes engineering, procurement, construction, pre-commissioning, commissioning (EPC), start-up and operations and maintenance work for the main central processing facility (CPF) and associated infrastructure. This includes the 162 km pipeline to the tank farm in Ahmadi. The project includes the EPC of a Production Support Complex.

One of the many turquoise wells hard at work. Wells are grouped into a certain sequence within a dedicated area of the reservoir and this grouping is referred to as a ‘pattern’. Each pattern has 36 or 42 wells.

The pipes of the ISS glisten in the Kuwaiti sunshine. All patterns are connected to the field’s two Infield Satellite Stations (ISS) – the intermediate collection point for the oil. The first separation of oil and water takes place here before the oil is pumped to the CPF. Gas from the wells is also utilised for firing the CPF’s steam generators.

Immense water storage tanks for boiler-grade water at the CPF. Managing the quality and quantity of water is one of the key features of the CPF. Water for field operations comes from the Al-Sulaibiya station 123 km away. It then goes through a treatment plant which can process an incredible 1,350 cubic metres of water per hour – to give you an idea of what a huge volume this is, an Olympic swimming pool contains 2,500 cubic metres. The boiler-grade water is then used in the steam generators below.

Towering steam generators are perhaps the most striking pieces of equipment onsite and they take on a different appearance from day to night. Made from carbon steel and with a capacity of 57 tons/hr of steam, they are absolutely pivotal in the project, as they generate the steam needed to inject into the wells and lower the viscosity of the oil.

Workers next to the process area where the oil is cleaned and treated. Sand is removed and any remaining water is also separated out. The extracted oil is piped to southern Kuwait for shipping around the world, so this is a critical stage to avoid any corrosion of this pipeline. Meanwhile, the water with traces of hydrocarbon is returned to disposal wells in the desert, while sand is disposed of in a designated zone. In future, an additional water treatment plant will be set up to treat and recycle this water for the generation of steam.

One of three huge tanks for storing the treated oil – each one can store 60,000 barrels of oil. Once the oil is cleaned it is stored in these export tanks, where it remains until it is exported to another tank farm in the south of Kuwait.

Fire water tanks and pumps in the CPF area – which are crucial to the safety of the site.

Mission control for the plant. Plant operators monitor and control operations from here 24/7.

Finally, the heavy crude is transported from the CPF to a tank farm 162 km away in Ahmadi, so the oil can be shipped from nearby ports.

Petrofac upgraded the technology and equipment in the south’s Crude Oil Control Centre. This centre also controls the blends of heavy oil from the Ratqa field in the north with lighter crudes from the south using a blending package provided by Petrofac.

We also migrated the existing control facilities for the entire Kuwait operations into this new building, using the latest state-of-the-art Orion operations and monitoring consoles to improve the effectiveness of operations.

INSERT MAP

Finally, the heavy crude is transported from the CPF to a South Tank Farm 162 km away in Ahmadi, near the border with Saudi Arabia, so the oil can be shipped from nearby ports. The first batch of oil from Lower Fars has now been exported from the site to a refinery in Kuwait. In the coming weeks, the first official shipment of half a million barrels of oil will also leave the facility.