WORDS PETER HALLIDAY

PUBLISHED APRIL 2021

PETROFAC IS TEAMING-UP WITH REPSOL SINOPEC AND TECHNIPFMC TO MAXIMISE THE RECOVERY OF NORTH SEA RESERVES – IN A WAY THAT IS COST-EFFICIENT AND ENVIRONMENTALLY FRIENDLY

HOW WE WORK

Industry collaboration – the key to recovering more from mature basins?

As one of the world’s most mature oil and gas producing regions, the North Sea has become a test bed for innovation. The challenge for the industry, backed by a statutory obligation set by the UK government, is to find new ways to get more hydrocarbons out of the ground in an economically viable manner. And, despite the fact that these hydrocarbons are getting ever more difficult to access, production costs in the region have fallen by an estimated 50% per barrel over the past five years.

Going forward, the challenge is not just to continue on this same trajectory, but to do so in a way that also reduces carbon intensity. Simply put, the industry imperative is to recover more hard-to-reach oil and gas reserves, for progressively less money as well as fewer emissions per barrel.

One innovation designed to help the industry to meet this challenge is the formation of an intriguing new alliance involving Petrofac, Repsol Sinopec Resources UK and TechnipFMC.

INTEGRATED, TECHNICALLY ROBUST AND COMMERCIALLY FLEXIBLE

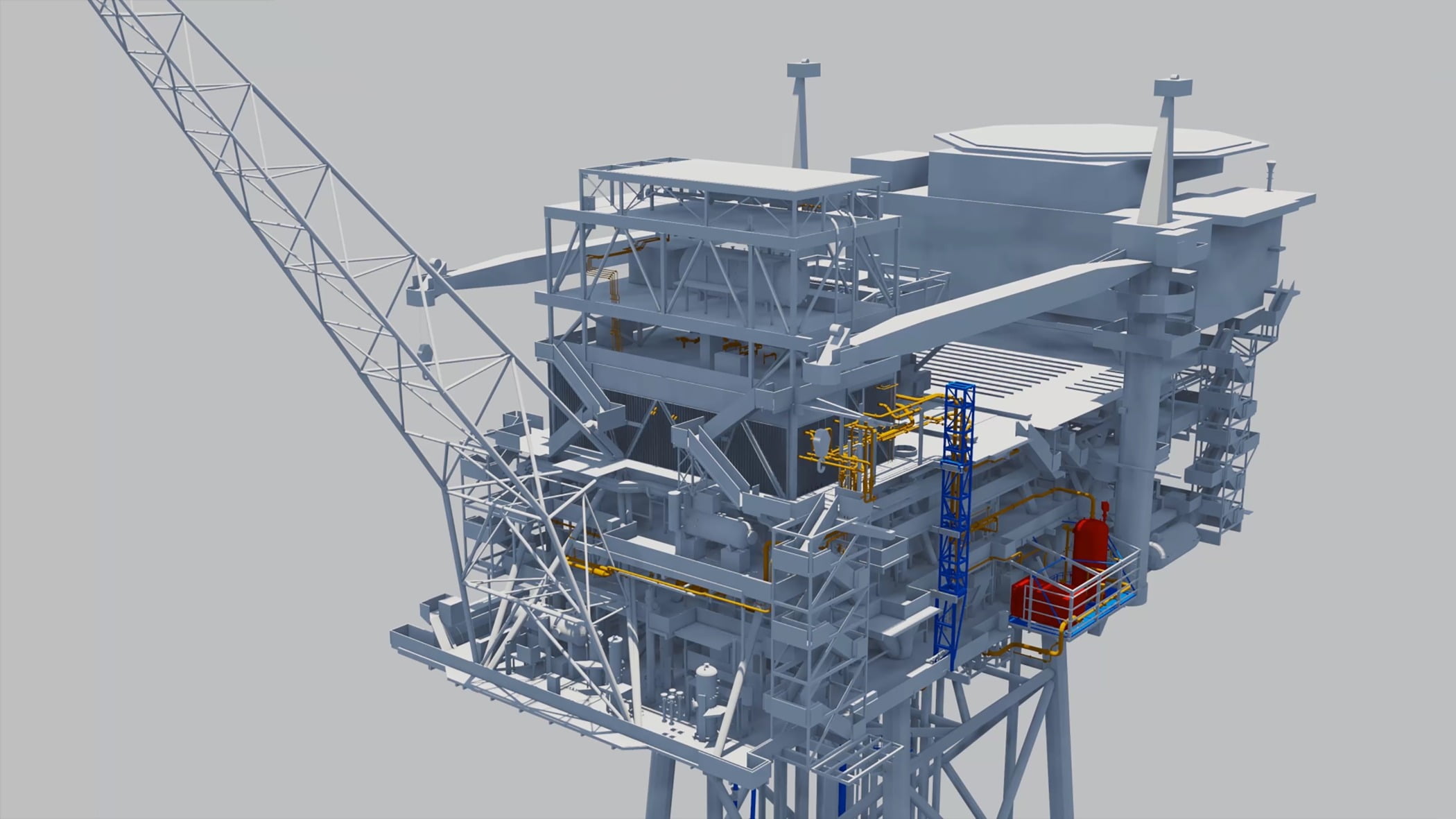

The alliance revolves around four of Repsol Sinopec’s existing infrastructure hubs in the North – for which Petrofac already provides operations, maintenance and engineering services.

The trio of firms are able to offer the owners of nearby oil and gas reserves an integrated, technically robust and commercially flexible solution to tie-back their fields to Repsol Sinopec’s hubs. Combining decades of subsea and topsides engineering, project management and operating expertise, the alliance creates an all-encompassing offering to support owners to take their hydrocarbons all the way from the well head to the export route.

“Traditionally, a resource holder would have negotiated with the owner of the operations hub, then parcelled up a series of engineering assignments, put them all out to tender, and worked through them sequentially,” explains Ed Jones, Head of Business Development for Petrofac’s Engineering & Production Services (EPS) West business. “By offering an integrated, pre-parcelled solution with a choice of commercial models, the alliance offers a much quicker, simpler, more cost-effective alternative. In fact, we can probably reduce the schedule time by 30%, with a commensurate cost decrease.”

SMALL POOLS, BIG OPPORTUNITY

The scale of the opportunity is significant. The UK Oil & Gas Authority estimates that the North Sea is home to the world’s greatest concentration of undeveloped marginal fields, locking-in more than three billion barrels-worth of hydrocarbons.

Thanks to recent engineering innovations, tie-backs can go further than ever before. “Just a few years ago, the viable length of a subsea tie-back, connecting a well head to an operating asset, would have been around 10 kilometres. Now, even with high-temperature, high-pressure reserves, it’s perfectly feasible to reach 50 kilometres, with some tie-backs stretching to more than 100 kilometres. It’s thought that at least half of future development activity in the North Sea will involve tie-backs,” explains Ed Jones.

REDUCING THE CARBON INTENSITY OF FUTURE OPERATIONS

There is also an important environmental aspect to the story.

“It fits in perfectly with the decarbonisation of North Sea operations,” continues Ed. “By extending the use and the life of existing infrastructure, and taking account of the carbon that’s already been embedded in its creation, future production becomes far less carbon intensive.”

This means that a proportion of the UK’s future demand for hydrocarbons, which will continue to be substantial for the coming years, can be satisfied locally in a more carbon-efficient manner.

STRATEGIC SIGNIFICANCE FOR PETROFAC

The alliance also has wider strategic significance for Petrofac.

“I like the model on a number of levels,” explains Nick Shorten, Managing Director of EPS West.

“First, it deepens our relationship with a key customer. Repsol Sinopec initiated the partnership and, to be accepted into it, we had to go through a rigorous selection procedure, against fierce competition. We had to earn our place.”

“Second, it demonstrates the extent to which we have integrated digital technologies into our work. The systems that underpin our brownfield modifications and projects work, support us to be more predictable in order to work with less cost and more speed. They also provide greater insights than ever before on improving safety.

“Third, it helps us to grow our brownfield capabilities. In a mature basin like the North Sea, where operators are looking to add more tie-backs and share infrastructure, this is a growing opportunity.

“Finally, it is an innovative model that, when proven, could be replicated elsewhere in other mature regions, like South East Asia.”

“The alliance offers a much quicker, simpler, more cost-effective alternative. We can reduce the schedule time by 30%.”

Ed Jones

“It is an innovative model that, when proven, could be replicated elsewhere in other mature regions, like South East Asia.”

Nick Shorten

A POSITIVE EARLY RESPONSE – WITH POTENTIAL FOR LONG-TERM IMPACT

“The early response from the market has been inquisitive and positive,” says Ed Jones. “The people I have spoken to believe it to be trail-blazing and novel, they like the way it brings more integration of the supply chain with customers, and they see how it contributes to the UK strategy of maximising economic recovery.”

Above all, the alliance and its approach helps to overcome one of the biggest barriers facing the North Sea operations. Back in 2019, the University of Oxford published an influential report on the future prospects of oil and gas production in the UK. One of the central conclusions was that “preventing the ‘premature’ decommissioning of infrastructure in mature areas and the ‘stranding’ of known resources will be a constant challenge”.

The alliance helps UK companies overcome this challenge – and, ultimately, the learnings could be applied in other mature basins across the globe.