MAKING MIRACLES IN OMAN

WORDS CHRISTINA McPHERSON

PUBLISHED APRIL 2021

WHere we work

THE PETROFAC RESEARCH CHAIR IN RENEWABLE ENERGY AT THE AMERICAN UNIVERSITY OF SHARJAH IS AIMING TO MAXIMISE THE PERFORMANCE OF SOLAR PANELS – AND THE RESEARCH COULD HELP OUR CLIENTS IN THE REGION MINIMISE THE ENVIRONMENTAL IMPACT ON THEIR PLANTS. HERE’S HOW

CATCHING THE SUN

HOW WE WORK

Think of sources of energy in the UAE, and you might automatically picture the region’s rich reserves of oil and gas. But there is another plentiful energy source in the sky rather than deep underground, and research backed by Petrofac is seeking to develop its potential.

Nearly 10 years ago, we created the Petrofac Research Chair in Renewable Energy with the American University of Sharjah (AUS). The aim of the programme is to pioneer renewable energy research and develop alternative energy technologies. The Renewable Energy Research Centre (RERC) was then established in 2017 under the umbrella of the Petrofac Chair Endowment, with a particular focus on solar energy, energy efficiency and remote monitoring.

“There is an abundance of solar energy in the Middle East – so why don’t we take advantage of it?” asks Professor Rached Dhaouadi, Research Chair. “Our aim is to maximise the efficiency and minimise the costs of solar farms within the UAE. It’s a win-win situation, you get more energy, it’s clean energy, it’s sustainable, it’s always there.”

One of Petrofac’s projects in New Zealand

Leading the way: American University of Sharjah working with Petrofac to optimise solar farm efficiency

MAKING THE MOST OF THE SUN

The University’s research is centred around three key areas affecting solar energy systems: efficiency and Internet of Things (IoT) monitoring, inspection through remote digital and thermal photography, and automated robotic cleaning.

“The environment and weather play a big role in the UAE and our research seeks to address these issues and study the effects on solar energy,” explains Rached. “What is characteristic of the UAE is the desert and its wind storms. Dust accumulates quickly on panels and when this happens, it reduces their efficiency. We wanted to quantify this, because if you have a solar farm with tens of thousands of panels, maintenance is a major cost that has to be addressed. But to be able to analyse energy systems you need big data.”

The University has built a small edge monitoring device that allows researchers to measure the efficiency of a panel and its environmental conditions (sun irradiance, temperature, etc.); it works remotely using the IoT, storing data in the Cloud. Eventually, thousands of panels could be connected to these devices for online monitoring and data collection.

Another initiative involves monitoring the panels by using drones to take digital and thermal images. This allows operators to monitor their condition and schedule cleaning and maintenance. It’s a promising technique, albeit one that has brought further problems to solve.

“We need to develop drones that can be operated remotely and cover large areas,” adds Rached. “The first step is developing autonomous drones that can recharge themselves wirelessly and then fly again. We are also developing a drone with a solar panel on top, which won’t need to land to charge. As long as there is sun, the drone can fly. We’re the first in the country to demonstrate the possibility.”

“Our aim is to maximise the efficiency and minimise the costs of solar farms within the UAE.”

Rached Dhaouadi

SOLAR SOLUTIONS: BEHIND THE METER

Mark Cowley is leading the operational side of Petrofac’s clean energy offering and highlights that offshore wind, carbon capture, hydrogen and waste-to-value sectors as key areas of focus. Solar is a small part of Petrofac’s New Energy Services, but it’s nevertheless an important element of our wider portfolio and can support our journey to Net Zero by 2030.

“Clean energy and renewables are a burgeoning market globally as countries strive to achieve the climate objectives agreed in the Paris Agreement,” comments Mark.

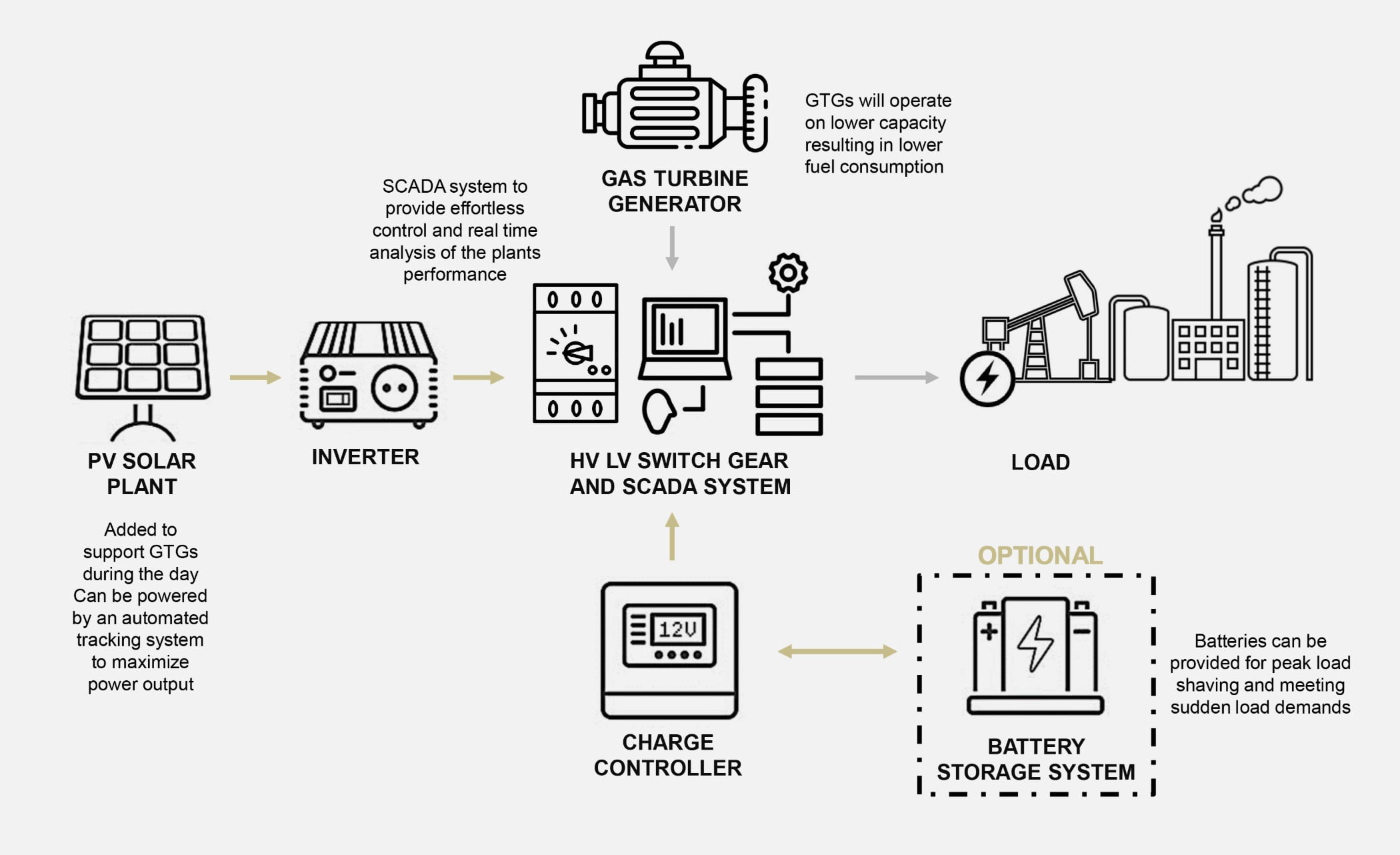

Solar energy rather than gas can be used to power customers’ plants and refineries during the day. This hybrid power generation technology is, he says, a great example of the clean energy solutions we’re looking to deploy on our projects to support our Net Zero goals and help our clients reduce their carbon footprint.

“Most of our potential projects are what we call ‘behind the meter’ projects. Usually, customers have their own power generation onsite and use Gas Turbine Generators. Typically, they want to lower the amount of gas they are burning to power their facilities,” he says.

“Gas is a valuable commodity. And as a hydrocarbon, when you burn it – even in a gas turbine which is a relatively clean way of generating electricity – you are generating CO2 which is harmful to the environment. Using solar power during the day will reduce the burden on gas turbines in the field, which can then be used at night. Integrating a solar photovoltaic farm with Gas Turbine Generators will provide a cleaner, more sustainable hybrid solution.”

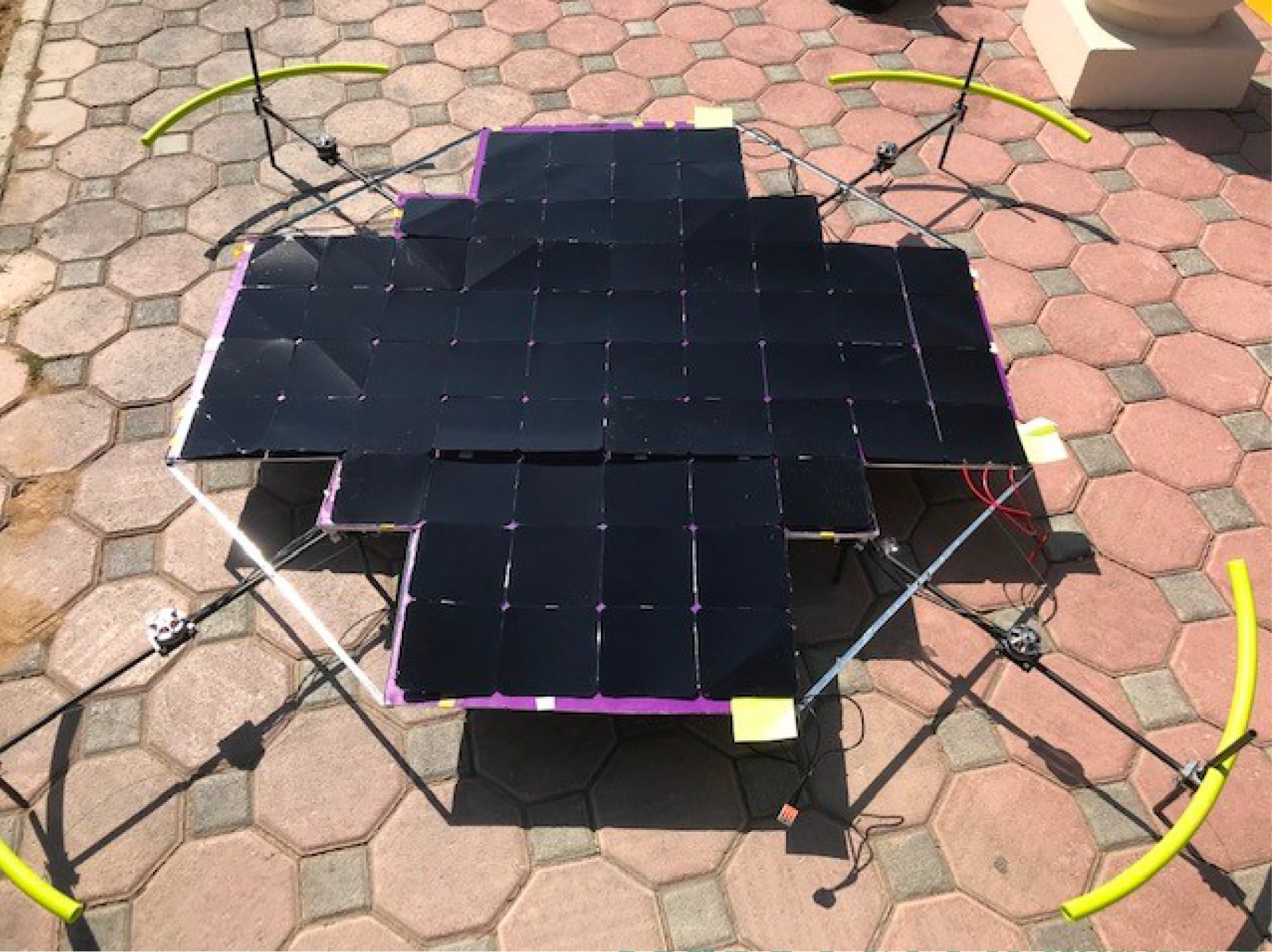

Country-leading technology: while the sun shines, this 2m2 solar-powered prototype drone will fly

One of Petrofac’s projects in New Zealand

How it works: the solar/gas hybrid solution

Compared to refineries, solar photovoltaic farms are relatively simple projects, and Petrofac has the in-house capability to develop, design, construct, and procure the materials and equipment needed for solar projects.

“We are focused on promoting our solar PV capabilities to oil and gas companies and have a competitive advantage in this area compared to organisations that build solar farms for the generation of electricity for the public,” explains Mark. “We are very familiar with the construction and operational challenges of working in a major hazard industry.”

“We can offer end to end services that support the full life cycle of solar projects, from system and technology assessment and selection, to project development support through to design, construction, operation and maintenance.”

Mark believes that the research AUS is carrying out will be invaluable in maximising the life cycle of solar farms in the future. Manufacturers claim very high efficiency rates, but these are in perfect conditions, and of course perfect conditions don’t exist, he says.

“The degradation in performance can be quite dramatic, so it’s equally important to consider those aspects in your design and construction. If you can squeeze more economic value out of a solar farm in terms of performance, revenue and power output, this equates to cost behind the meter – as you’re saving gas which is itself a commodity.”

“Clean energy and renewables are a burgeoning market globally as countries strive to achieve the climate objectives agreed in the Paris Agreement.”

Mark Cowley

BRIGHTER FUTURES

While the Research Chair could have a lasting influence on solar energy and the wider region, it’s also beneficial on a personal level for those involved.

The Chair has a multi-discipline team bringing together computer engineering, electrical engineering, and chemical engineering. Faculty members, research assistants, undergraduate students and graduate students have the opportunity to attend the research centre.

“We are preparing our future engineers to be more aware of clean energy. More and more students are interested in renewable energy and working on projects in this area that further their development,” says Rached.

And, there’s opportunities for Petrofac’s young engineers too. “They will carry what they learn over to projects that we design, so there is that benefit as well. The automation and aerial assessments that AUS are advancing can also speed up design prototyping and potentially help us make more accurate assessments before our project teams put boots on the ground - or the roof ! ” says Mark.

“AUS’s research will eventually lead to the commercialisation and practical implementation on many solar projects. I’m proud we’ve invested in that.”

RESILIENT AND READY FOR WHAT COMES NEXT

The coming together of these two complementary companies has, from Jason’s perspective, been “a smooth and frictionless transition”.

John agrees. He says that Jason and his team are excellent to work with and that a culture of safety – and putting people first – was something that immediately united the two companies. “Our people are the greatest asset in Petrofac, and we wake up every day making sure we do the right thing for each other,” he adds.

And, while the Permian Basin, like the industry around the world, has seen a downturn caused by the uncertainty of the pandemic, Petrofac and W&W Energy have been able to weather the storm together.

Despite the challenges, they have also won new clients this year. “We’re in different markets now from when the acquisition happened – we’ve gone from only working with upstream clients to working with midstream and even a little bit of downstream,” says Jason.

W&W has been able to build up their brand in the field. “The way we present proposals and communicate with clients is much more sophisticated than it used to be because of Petrofac, and it’s got us some wins in the last three months,” adds Jason.

It’s apparent that both companies are resilient and seek out opportunities. Petrofac has already been able to use its engineering expertise to drive savings for clients, offering creative ways to re-purpose existing client inventory to support in-field improvements (see box out).

Since the merger, W&W Energy has focused on enhancing its fleet, adding a new large knuckle boom truck (one of only two of its type in the whole region) and investing in new hydro testing equipment to support its pipeline integrity service. They have both stayed busy during the downturn.

“The field is already picking up. As that continues we are in a good position to take on larger projects and have the financial strength to be able to assist customers in the procurement process,” says John.

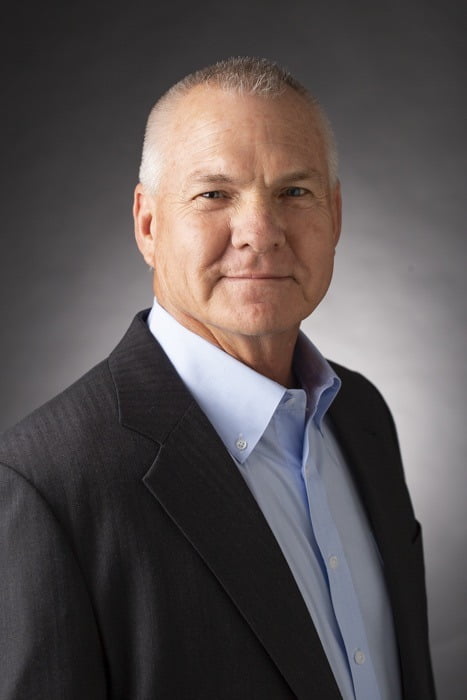

JOHN GLITHERO

President of Petrofac America

A native of Texas, John has more than 30 years’ experience in the oil and gas industry, including tenures as Senior Vice President, Business Development for Wood Group Americas, and prior to that, President of Wood Group (WGPSN). He joined us in 2017 and leads all elements of our growth and operations in the region.

JASON WATERS

W&W Energy Services President

Jason is from a small community of about 200 people in the Permian Basin. He attended the United States Military Academy and served in the US Army for five years. On leaving the army he took over the leadership of W&W Energy and over ten years grew the business into the success it is today.

ONE FOR THE HISTORY BOOKS?

The rest, as they say, is history.

“What we achieved, especially between April and July 2020, was phenomenal,” adds Construction Director Mohammed Shaheen. “As the Covid-19 pandemic intensified, we felt insulated from it, as though our site was the safest place on earth. And, as the whole world came crashing down, Ghazeer kept pushing forward.”

Ultimately, the project was delivered two months early. Some 19 million hours were safely completed, without a single lost-time incident (LTI). bp was able to put the project into production in October 2020. And this will surely go down in the annals of Petrofac history as one of the company’s most impressive performances.

Mohammed Shaheen

Learning there was unused, spare equipment within the client’s inventory, from transformers and switchboards to pumps, VFDs and control panels, they started to look at ways to release this inventory and provide immediate savings.

They surveyed every piece of existing equipment, working alongside client and vendor personnel. The electrical engineering team validated the existing power distribution equipment. And, they wrote scopes of work and requests for quotations (RFQs) for vendors to carry out the minimum modifications, refurbishment and testing required to enable the use of more than 50 electrical and mechanical equipment items that were already in the client’s inventory.

This creative, collaborative way of working has helped the client deliver vital infrastructure improvements even when budgets were constrained. New CAPEX for this first campaign will be reduced by over $1.5 million, a saving of more than 10% of the total installed cost (TIC).

NIMBLE ENGINEERING

What started out as a small scope to provide the detailed design package for the installation of water booster pump stations, evolved into a comprehensive programme to deliver a standard optimised design that would deliver year-on-year savings for a client in the Permian Basin.

During initial planning Petrofac and W&W Energy established that the client’s plan was to install between 40 and 50 of these booster pump stations over the next few years to meet its increasing production targets. With support from them, Petrofac and W&W Energy began developing a ‘design one, build many’ standardised design that would drive costs down by optimising the mechanical and electrical and instrument designs.

However, before the standardised builds could begin, the downturn saw CAPEX cut across the region. With a number of pump stations still needed to support the infrastructure, the Petrofac and W&W teams worked with the client to develop an alternative solution that would support them during this time.